- Home

- Case studies

- CASE1

Case studies

CASE1

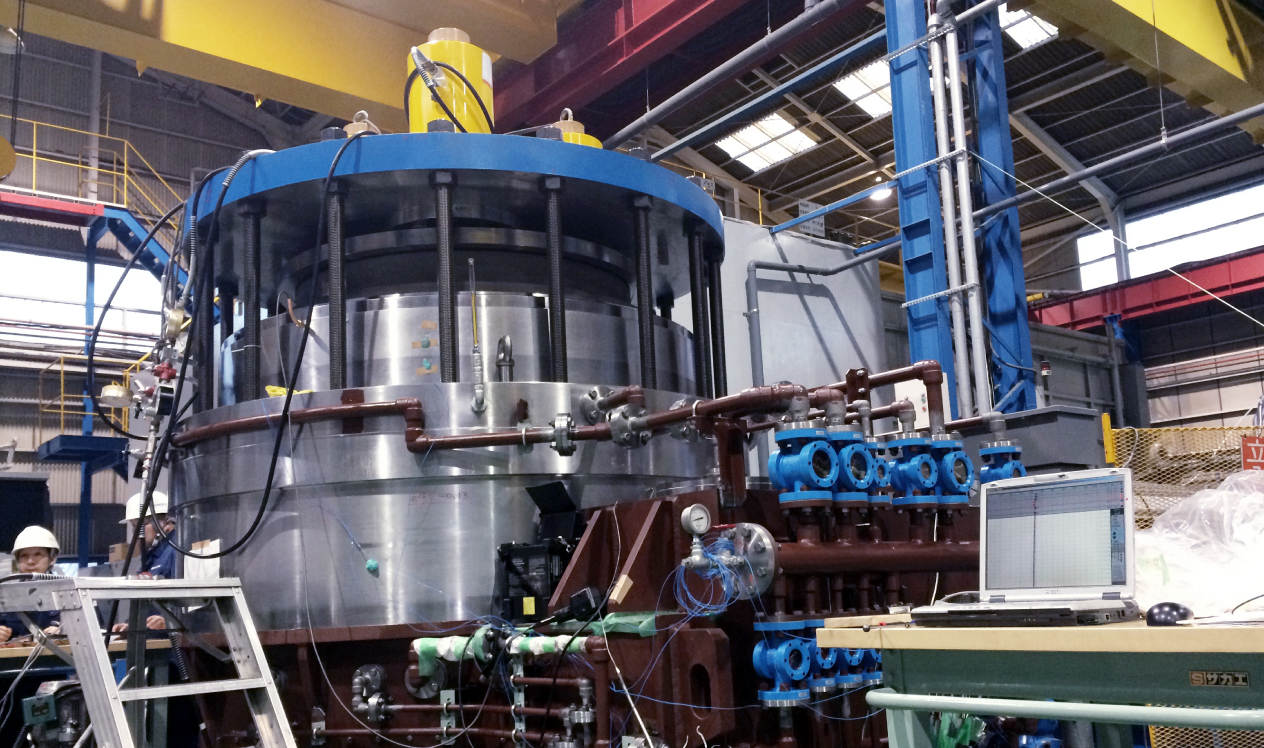

Provision of low maintenance cost gearbox for a power plant

1

Issues and background

Due to the shutdown of the whole nuclear power plants caused by the earthquake in 2011, the old coal-fired thermal power plants were forced to operate at full capacity, leading to extremely high maintenance costs associated with its structure. Electric power companies were facing the challenge of providing a stable supply of electric power under extremely severe conditions.

2

Initiatives to strive to solve issues

The original design was composed of parts that required special production equipment. This meant that maintenance was only possible on a limited number of sections and costs remained high. We were able to offer the new gearboxes based on modern design at a cost equivalent to the cost of one session of maintenance, with significantly reducing the potential cost of maintenance in the future.

3

Results and future developments

In the verification process, the company applied its various types of load testing equipment to enhance the product quality, together with dynamic and static tests such as 300% overload element tests.

This is a project to solve social issues that was able to contribute to a socially important power generation business by boldly and enthusiastically facing risks, while breaking free from the restriction of self-estimation.

Inquiries

Please feel free to contact us

with any questions or requests and for quotations.